Non-woven coir geotextiles are game-changers in erosion control and landscaping. Unlike traditional materials, they offer superior strength and durability while being eco-friendly. These permeable fabrics, such as geotextiles and erosion control blankets, help retain soil moisture and promote plant growth, making them ideal for sustainable practices. They provide an effective barrier against weeds and erosion control applications without harming the environment. As more industries shift towards green solutions, non-woven coir geotextiles, an alternative material, stand out as a reliable choice. Their versatility makes them suitable for various applications, from agriculture to construction. Discover how these innovative products can transform your projects today.

Understanding Geotextiles

Definition and Purpose

Geotextiles are synthetic or natural fabrics, woven preparations or coir yarn used in civil engineering. They help with soil stabilization and drainage. Non-woven coir geotextiles are made from coconut fibers. These textiles prevent soil erosion and support vegetation growth. Their porous nature, like non-woven coir geotextiles, allows water to pass through easily, which helps maintain soil moisture.

Types of Geotextiles

There are two main types of geotextiles: woven and non-woven. Woven geotextiles consist of interlaced fibers. They provide high tensile strength. Non-woven geotextiles, like coir, offer excellent filtration properties. They are often used for erosion control and landscaping projects. Some examples include woven geotextiles, non-woven coir geotextiles, geotextile sand bags, and geo textiles used in road construction.

Role in Soil Stabilization

Geotextiles play a crucial role in soil stabilization. They improve the load-bearing capacity of the ground. By using geo textile materials, engineers can create stable foundations for roads and buildings. These woven geotextiles also reduce the movement of soil particles, preventing erosion during heavy rains. Their use, including woven geotextiles and non-woven coir geotextiles, is essential in areas with loose or unstable soils.

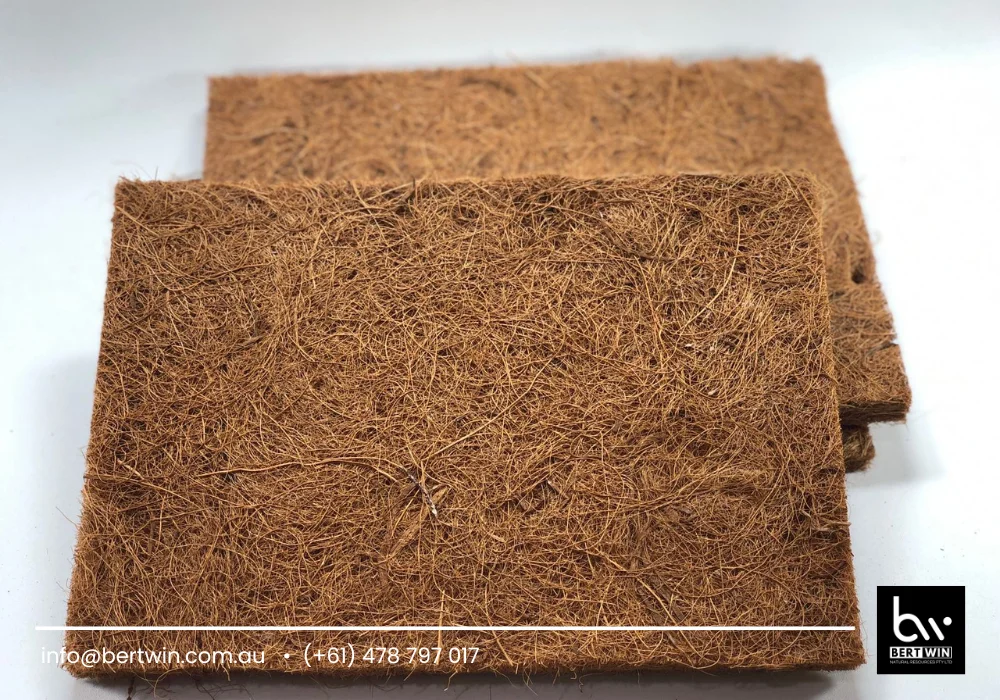

Non-Woven Coir Materials

What is Coir

Coir is a natural fiber extracted from the husk of coconuts. It has been used for centuries in various applications. Coir fibers are strong and durable, making them ideal for products like ropes and mats. The fibers can be processed into different forms, including non-woven coir geotextiles. These materials offer unique benefits in soil stabilization and erosion control.

Unique Properties of Coir

Coir possesses several unique properties. It is naturally resistant to saltwater, which makes it suitable for coastal areas. The fibers have excellent water retention capabilities. This helps in maintaining soil moisture levels. Coir’s open weave design allows for good drainage while preventing soil loss. It is biodegradable, breaking down over time without harming the environment.

Advantages Over Synthetic Options

Non-woven coir geo textiles provide advantages over synthetic materials. They are more environmentally friendly because they decompose naturally. This reduces plastic waste in landfills and oceans. Coir fabrics also promote healthy plant growth by allowing air and water to reach the roots efficiently. Their durability ensures that they can withstand harsh weather conditions better than many synthetic options.

Benefits of Coir Geotextiles

Environmental Impact

Coir geotextiles play a vital role in environmental protection. They are made from natural fibers, which makes them biodegradable. This reduces waste in landfills. When used in erosion control, coir geotextiles help stabilize soil. They promote vegetation growth by retaining moisture and nutrients. Natural habitats benefit from this as plants grow more effectively.

Cost-Effectiveness

The price of coir geotextiles is competitive compared to synthetic alternatives. Their longevity and effectiveness can lead to cost savings over time. Users often find that investing in coir geotextiles reduces maintenance costs. For instance, gsm coir geotextiles provide excellent performance without frequent replacements. This makes them a smart choice for various projects.

Durability and Strength

Coir geotextiles offer impressive durability. They withstand harsh weather conditions and resist degradation. The strength of these materials ensures they remain effective over time. Users can trust coir needle felt geotextile rolls for heavy-duty applications. These rolls maintain their structure under pressure, making them suitable for construction and landscaping.

Applications in Engineering

Erosion Control

Coir geotextiles play a crucial role in erosion control. They help stabilize soil in areas prone to erosion. When placed on slopes, they reduce the speed of water runoff. This slows down soil loss and promotes vegetation growth. The natural fibers are biodegradable, making them an eco-friendly choice.

Projects using coir geotextiles often show improved results. For example, riverbanks reinforced with woven geotextile textiles demonstrate less erosion over time. Studies indicate that coir can last for several years while supporting plant life.

Road Construction

In road construction, coir geotextiles serve as a valuable engineering material. They provide reinforcement for subgrade layers. This increases the overall stability of roads and reduces maintenance costs. Engineers often use them to prevent soil displacement during heavy traffic.

Coir helps manage drainage effectively. It allows water to pass through while holding soil in place. This feature is essential for maintaining road integrity during rainy seasons.

Landscaping Projects

Landscaping projects benefit from the use of coir geotextiles as well. They assist in creating effective biodegradable applications for gardens and parks. Coir mats can suppress weeds while allowing air and moisture to reach the soil.

Moreover, they enhance aesthetic appeal by promoting healthy plant growth. Landscapers appreciate their ability to blend into natural environments while serving functional purposes.

Manufacturing Process

Production Steps

The production of non-woven coir geotextiles involves several key steps. First, coir fibers are extracted from coconut husks. This is done by soaking the husks in water to loosen the fibers. After extraction, the fibers are cleaned and dried.

Next, the fibers undergo a carding process. This process aligns the fibers and prepares them for bonding. Then, they are laid out in a mat form. The final step involves bonding the fibers together using heat or adhesive. This creates a strong and durable material suitable for various applications in engineering.

Available Densities

Non-woven coir geotextiles come in different densities. Typical densities range from 200 to 800 grams per square meter (gsm). Lower density options are lighter and more flexible. They work well for erosion control on gentle slopes.

Higher density geotextiles provide greater strength and durability. These are ideal for projects requiring heavy load support. Engineers often choose the appropriate density based on specific project needs.

Factors Affecting Performance

Several factors influence the performance of non-woven coir geotextiles. Moisture content plays a crucial role in their effectiveness. High moisture can weaken the structure over time.

l type also affects performance. Certain soils may require specific types of geotextiles for optimal results. Environmental conditions, such as temperature and exposure to UV light, also impact durability.

Final Remarks

Non-woven coir geotextiles are game-changers in engineering and environmental protection. They provide robust support while being eco-friendly. You can trust their durability and effectiveness in various applications, from erosion control to landscaping. The manufacturing process ensures high quality, making them a reliable choice for your projects.

As you consider materials for your next venture, think about the advantages coir geotextiles bring. They’re not just sustainable; they’re also cost-effective and versatile. Dive deeper into how these innovative materials can elevate your work. Explore your options today, and make a difference with non-woven coir geotextiles!

Frequently Asked Questions

What are non-woven coir geotextiles?

Non-woven coir geotextiles are biodegradable fabrics made from coconut fibers. They provide soil stabilization, erosion control, and enhance plant growth.

How do non-woven coir geotextiles differ from woven ones?

Non-woven coir geotextiles are produced by bonding fibers together rather than weaving them. This results in a thicker, more absorbent material suited for erosion control.

What are the benefits of using coir geotextiles?

Coir geotextiles offer numerous benefits including biodegradability, excellent water retention, soil protection, and promoting vegetation growth. They are eco-friendly and sustainable.

Where can I apply non-woven coir geotextiles?

These geotextiles are ideal for landscaping, slope stabilization, road construction, and environmental restoration projects. They effectively prevent soil erosion in various applications.

How are non-woven coir geotextiles manufactured?

The manufacturing process involves collecting coconut fibers, cleaning them, and then bonding them through needle punching or heat treatment to create a durable fabric.

Are non-woven coir geotextiles environmentally friendly?

Yes, non-woven coir geotextiles are made from natural materials and are fully biodegradable. They contribute positively to the environment by reducing plastic waste.

How long do non-woven coir geotextiles last?

Typically, non-woven coir geotextiles last between 2 to 5 years depending on environmental conditions. Their lifespan is sufficient for effective soil stabilization and plant growth support.

In conclusion, if you are eager to delve deeper into the details of coir products, feel free to explore our website. Additionally, for direct and instant connection with our team, you can reach us through the following WhatsApp link +61412773364. We look forward to providing you with the information and assistance you need.